New system for batteries

ENERGY STORAGE SYSTEM ON THE SEPARATOR

New electrode printing system for any energy storage system on the separator on both sides, thus avoiding the use of metallic collectors, such as copper, aluminium, steel, etc.

By treating the electrode inks with graphene carbonaceous materials, an optimum electrode conductivity is achieved for the chemical and electrochemical reactions to take place during the charging and discharging processes, without the need to use a metal collector as a support.

This new technology off ers numerous advantages for energy storage systems, such as increased energy density, lower cost, higher cell voltage, etc.

In collaboration

Development potential

ELIMINATION OF THE USE OF COLLECTORS

Metal current collectors are one of the heaviest components of energy storage systems and are hence involved in the reduction of energy density (Wh/Kg).

Collectors are one of the most expensive components of a battery, especially nowadays with the problem of material supply and geolocation. Up to now, the solutions that have been proposed have been to reduce the thickness of the collector as much as possible in order to reduce its weight and price, however, no one has ever done away with it.

Thanks to our new technology, the electrodes of the energy storage systems can be printed directly onto the separator, which signifi cantly improves their weight, price, and energy density.

Advantages

Advantages of using our development.

01

Higher energy density

by avoiding the use of metallic collectors, considerably reducing the total mass of the device. As a consequence, the energy density per kg (W·h/kg) will be improved.

02

Reduction of the final price

03

No collector oxidation/ reduction problems

04

Increased cell potential

Applications under development

versatile technology for any storage system

It is of interest to any company involved in the manufacture of energy storage systems, whether lithium batteries, sodium batteries, capacitors, supercapacitors, hydrogen cells, etc. As it is a very versatile technology for any storage system, the producer company could be able to market its products with the same (or sometimes better) performance, but at a much cheaper cost and better energy density per kg.

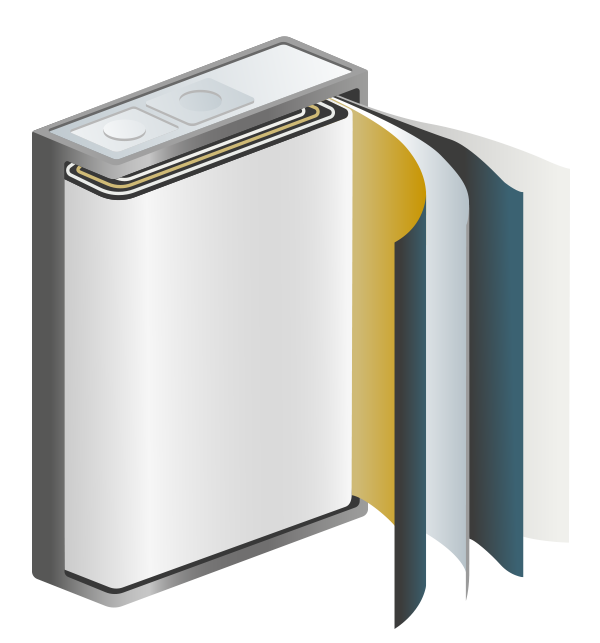

System Comparison

THE FUTURE IS HERE

Current system

Components of a lithium-ion (li-ion) battery

(Alluminium)

Cathode on aluminium

Anode on copper collector

Separator

Separator

Graphenano system

Components of a Graphenano battery

Container

Anode

Catode

Do you need further assistance?

ANY QUESTION WOULD BE SOLVED

Our technical support team will reach out to you shortly.

*Only corporate mail will be attended to.